SixSense, a Singapore-based deep tech startup, has secured $8.5 million in Series A funding to expand its AI-powered defect detection platform for the semiconductor industry. The funding round was led by Peak XV’s Surge (formerly Sequoia India & SEA), with participation from Alpha Intelligence Capital, FEBE Ventures, and others, bringing SixSense’s total funding to approximately $12 million.

Founded in 2018 by engineers Avni Agarwal (CEO) and Akanksha Jagwani (CTO), SixSense is addressing a critical challenge in semiconductor manufacturing: converting large volumes of raw production data into actionable, real-time insights that improve chip quality, yield, and operational efficiency.

AI-Powered Defect Detection in Real Time

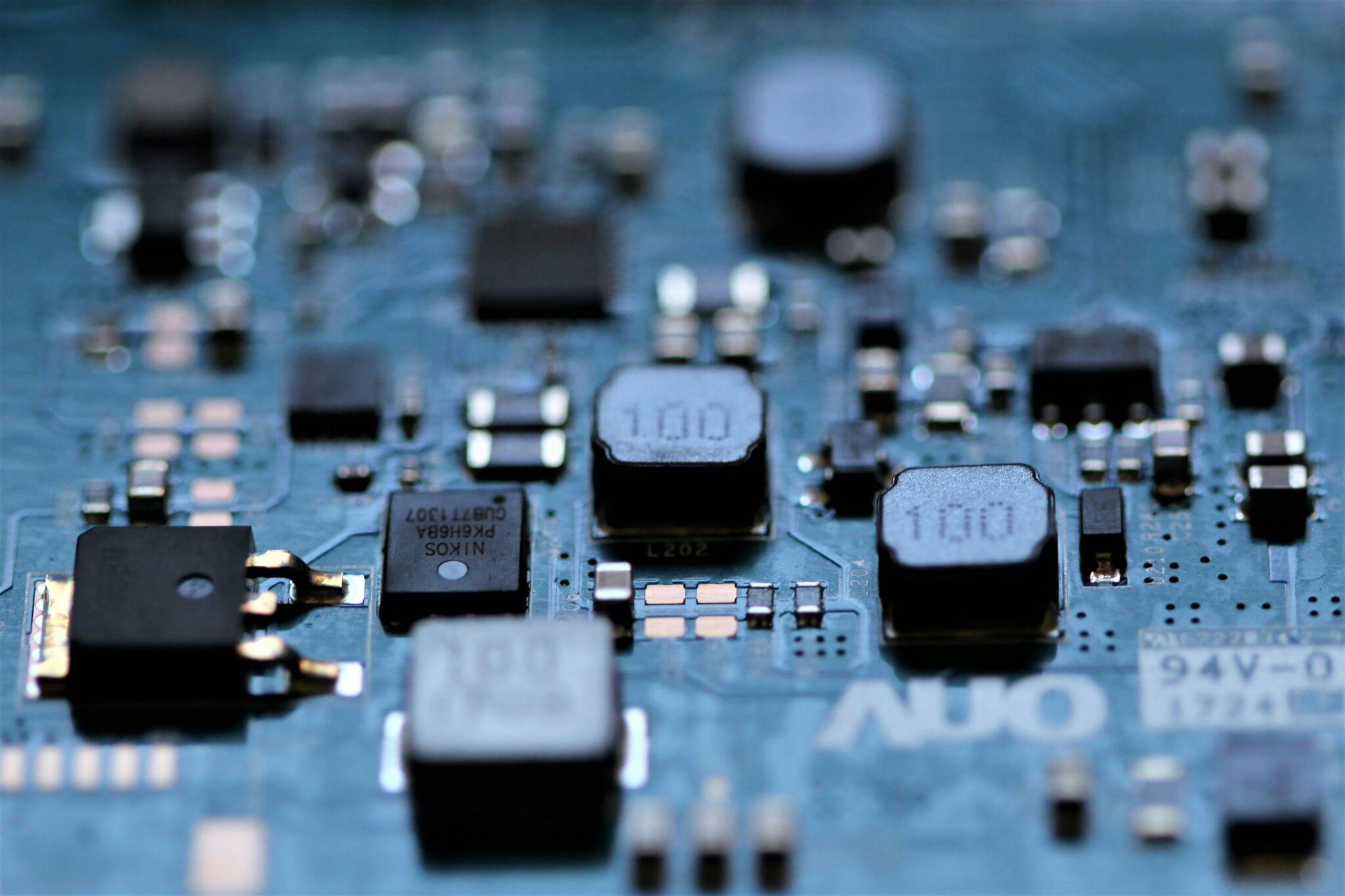

The SixSense platform uses machine learning and AI to analyze everything from defect images to equipment signals directly on the production line. While fabs generate massive amounts of data, most existing inspection systems provide only basic visualizations. Engineers are still left with the heavy lifting, analyzing SPC charts, spotting patterns, and performing manual inspections.

“That process is slow, subjective, and doesn’t scale,” said Agarwal. “Our AI platform gives engineers real-time alerts and predictive insights, helping them prevent issues before they escalate.”

The solution includes defect detection, root cause analysis, and failure prediction, and is designed specifically for process engineers, not data scientists. Engineers can train and deploy AI models in under two days using their own fab data, without writing a single line of code.

Proven Results in Global Chip Manufacturing

SixSense’s platform is already live in leading semiconductor facilities, including GlobalFoundries and JCET. According to the company, it has processed over 100 million chips, helping customers achieve:

- 30% faster production cycles

- 1–2% increase in yield

- 90% reduction in manual inspections

The system integrates seamlessly with inspection equipment covering over 60% of the global semiconductor market, positioning SixSense as a leading player in AI-driven chip quality control.

From Automotive to Semiconductors: A Strategic Pivot

Before focusing on semiconductors, Agarwal and Jagwani explored industries like aviation and automotive, but found the semiconductor industry ripe for disruption. Despite its reputation for precision, inspection processes in many fabs remain fragmented and highly manual.

Jagwani brings years of experience from Hyundai Motors, GE, and Embibe, specializing in software automation and manufacturing systems. Agarwal, a former Visa engineer, helped build large-scale analytics systems and had long envisioned applying AI to traditional industries.

Positioned for Global Expansion Amid Industry Shifts

As geopolitical tensions and U.S.-China trade conflicts drive a shift in global chip production, fabs are expanding rapidly across Malaysia, Vietnam, Singapore, India, and the U.S.. This realignment plays to SixSense’s advantage.

“New fabs without legacy systems are more open to AI-native tools like ours,” Agarwal said. “Being based in Southeast Asia allows us to support rapid expansion and modernization across key semiconductor hubs.”

SixSense’s target customers include foundries, IDMs (Integrated Device Manufacturers), and OSATs (Outsourced Semiconductor Assembly and Test providers). The company is already working with facilities across Singapore, Malaysia, Taiwan, and Israel, with plans to expand into the U.S. market.